Find our latest blog posts at https://www.modip.ac.uk/blog

Monday, 2 October 2023

Wednesday, 19 July 2023

PlasticsFuture 2023

|

| Revolution Plastics, University of Portsmouth. Image: Louise Dennis |

The three days were split into 6 sessions:

- Session 1: Microplastics - detection, transport and impacts for environmental and human health

- Session 2: Exploring the current issues of plastic use within the context of fashion and textiles and the role of plastics in the future

- Session 3: Plastic pollution in the Global South

- Session 4: The Plastics That Made Us

- Session 5: Creative Solutions to Global Challenges

- Session 6: Tackling plastic pollution: Global Change Perspectives

Session 1: Microplastics - detection, transport and impacts for environmental and human health

Description: Microplastics are everywhere in our lives, in the food we eat and the air we breathe. As research on microplastics gathers pace, it is becoming apparent that microplastics may impact human health and we need to understand how to limit our exposure.

There are currently many projects and policies looking at how to reduce plastic use in packaging but less understanding on how this will impact microplastic numbers. This session will take a closer look at the challenges and discuss possible solutions.

Themes:

- Methods of analysis - including data collection

- Citizen science

- Microplastics in water, land and air

- Microplastics human health implications

Keynote: Dr Ben Williams, Senior Research Fellow, Air Quality Management Resource Centre, University of the West of England

Short talks by:

- Dr Sakcham Bairoliya, Nanyang Technological University - The Big Picture: Microbial interactions within the plastisphere

- Delphine Ciréderf Boulant, Institut de Recherche Dupuy de Lôme (IRDL) UMR CNRS 6027 - Assessment of microplastic contamination of organic fertilisers applied to agricultural soils

- Nia Jones, Bangor University - Simulating the impact of estuarine fronts on microplastic concentrations in well-mixed estuaries

- Pei-Chen Lin & Yin-Yi Chen, Institute of Environmental and Occupational Health Sciences, National Taiwan University - Assessment of microplastics exposure from oral pathway in young adults: a pilot study in Taiwan

- Miguel A. Gomez Gonzalez, Diamond Light Source Ltd -Understanding how microplastics can act as transportation vectors of co-existing nano pollutants and their interaction within environmental solutions

- Dr Chunlei Fan, Morgan State University - Effect of High-Density Polyethylene Microplastics on Growth and Survival of Eastern Oyster Larvae in the Chesapeake Bay, USA

- Dr Judy Lee, Chemical and Process Engineering, University of Surrey - Nano/Microplastic induced membrane fouling and potential mitigation strategies

Session 2: Exploring the current issues of plastic use within the context of fashion and textiles and the role of plastics in the future

Description: An opportunity to discuss current issues of plastic use within the context of fashion and textiles. Each year, the industry uses 342 million barrels of petroleum to produce plastic-based fibres such as polyester, nylon or acrylic. This equates to 1.35 per cent of the globe’s oil consumption. Worse still, these plastic-based fibres are responsible for 73 percent of microfibers pollution in Arctic waters and, according to the Ellen MacArthur Foundation, the plastic packaging on which the fashion industry is largely reliant, is estimated to make up 26 per cent of the total volume of plastics created each year – 72 percent of which is thrown away. However you choose to measure its impact, the numbers are staggering. This session acknowledges these very pressing issues that the fashion industry and academia is currently facing.

We will bring together scholarly experts and practitioners in the areas of plastic use, materiality and design to share their knowledge and experiences with fellow academics and practitioners. Scholarly, conceptual and practitioner papers are welcomed, especially those that address the following themes:

Themes:

- Fashion lifecycles vs plastic lifecycles

- Alternatives to fossil fuel based plastics for fashion and textiles

- Recycling of plastics

- How can plastics fit within a sustainable future

- Solutions to microfibre pollution from textiles

- A transition to a circular economic environment

- Single use plastic in fashion retail

- Consumer intention behind recycled plastic waste product

Introduction: Noorin Khamisani and Karen Ryan, University of Portsmouth

Keynote: Kate Goldsworthy, Professor of Circular Design and Innovation, Co-Director, Centre for Circular Design (CCD), Deputy Director, Business of Fashion Textiles & Technology (BFTT), University of the Arts London (UAL), UK

Short talks by:

- Dr Claudia Henninger - Presented by: Libby Allen, University of Manchester - Microplastic fibres released during washing of clothing: the unseen side of fashion

- Lisbeth Løvbak Berg, Consumption Research Norway (SIFO), Oslo Metropolitan University - Textile waste – past, present and future? Synthetics in Norwegian textile waste in Norway 2000-2023

- Dr Shreyas Patankar, Ocean Wise Conservation Association - Wash cycle design can reduce microplastic emission from home laundry

- Professor Lisa Macintyre, Heriot-Watt University - Fibre Fragmentation Scale – evaluating a proposed new method for reporting the results of fibre fragmentation testing

- Dr Victoria Bemmer, University of Portsmouth - Enzymatic deconstruction of polyester textiles

- Emma Bianco, Pure Earth Collection Ltd - Fashion and the plastic consequences

Session 3: Plastic pollution in the Global South

Chair: Dr Cressida Bowyer - Senior Research Fellow and Deputy Director of Revolution Plastics, University of Portsmouth, UK

Keynote: Esrat Karim, AMAL Foundation - Plastic pollution in Bangladesh

Short talks:

- Professor Susan Jobling, PISCES - A Systems Approach to Preventing and Eliminating Plastic Pollution in Indonesian Societies

- Dr Fabrizio Ceschin & Dr Nazli Terzioğlu, Brunel University London - The PISCES Partnership Systemic Cross-Value Chain Design Approach to Tackling Plastic Pollution in Indonesia

- Cressida Bowyer, University of Portsmouth - Creative solutions to global challenges

Session 4: The Plastics That Made Us

Description: Focusing on the collections and exhibitions programme at the Museum of Design in Plastics (MoDiP), the only UK Accredited museum with a focus on plastics, this presentation will demonstrate how by learning from the past, manufacturers, designers, and consumers of plastics can make better informed choices. MoDiP's purpose is to use its Designated collection to develop understanding of the value of plastics within historical, contemporary, and sustainable contexts. Exploring the museum’s objects that encapsulate a variety of uses and activities - taking into account the clothes we wear, the games we play, and the environments in which we live - this keynote will show how valuable plastics, as a materials group, have been when used appropriately. It will also acknowledge the negative impact the poor use and disposal of plastics materials has on the environment and health.

Roundtable themes: The Care and Curation of Plastics

- Historical and contemporary cultural perceptions of plastics

- Curatorial relationships with plastics

- The seen and unseen uses of plastics

- Sustainability and the green consumer

- What can we learn about the future of plastics from their past?

Keynote: Dr Louise Dennis, Museum of Design in Plastics, Arts University Bournemouth - The Plastics that Made Us: The care and curation of plastics

Round table discussion:

- Dr Louise Dennis, Museum of Design in Plastics, Arts University Bournemouth

- Johanna Agerman Ross, Victoria and Albert Museum

- Dr Helen Peavitt , Science Museum

- Dr Susan Mossman, Plastics Historical Society

Session 5: Creative Solutions to Global Challenges

Description: Arts-based methods are increasingly being used in academic research to explore lived experience from a grassroots perspective. Artistic methods democratise the research process and disrupt traditional academic hierarchies, often revealing diverse values, and enhancing understanding. When communities collaborate with researchers to find solutions, the results are more local, targeted and contextually sensitive.

This session will include past and present projects in the Global South, methodologies and workshops.

Themes:

- Community-based participatory research

- The range of arts based methods

- Working in different contexts

- Practical workshops

Introduction: Dr Cressida Bowyer, University of Portsmouth

Part 1: The Role of community engagement in tackling plastic pollution

Keynote: James Wakibia, Role of individuals in the fight against plastic pollution

Short talks:

- Alice Darondeau, The SeaCleaners - The SeaCleaners

- Savannah Schaufler, University of Vienna, Austria - “Plast(dem)ic:” Materiality, Behavior, and COVID-19

- Luca Marazzi, Thames21 - Plastic litter has no place in the natural environment – key findings from the Plastic Free Mersey Project

- Victoria Prowse & Helen Powers, Environment Agency, East Midlands Regulated industry Team

Part 2: Participatory arts-based research methods: Examples from the global south

Keynote: Nelmo Newsong (Nelson Munyiri), Artist and Executive Director at Mukuru Youth Initiative - ‘Impact of creative methods in influencing social change’

Short talks:

- Angela McDermott, Waste Aid - MASIBAMBISANE: Towards a local circular economy in Mpumalanga, South Africa

- Nicola Hay, University of Portsmouth - IMAGINE PLASTICS; Immersive Experiences - SEEING IS BELIEVING

- Dr Leanne Proops, University of Portsmouth - Terrestrial Plastic Pollution and its Threat to Livestock and Livelihoods

Session 6: Tackling plastic pollution: Global Change Perspectives

Themes:

- Where are we after INC-2 (Intergovernmental Negotiating Committee session)?

- How can we build a ‘just’ transition into the treaty?

- Transparency and disclosure issues in policy development

- Reuse as an effective policy option

- Stakeholder perspectives

- Introduction: Professor Steve Fletcher, University of Portsmouth

- Jill Bartolotta, Ohio Sea Grant and The Ohio State University - Partners in Plastic Pollution Prevention: Reducing Plastic Pollution through Public and Private Partnerships

- Valérie Patreau, Polytechnique Montréal (QC, Canada) - Moving away from single-use plastics, public policies effectiveness and consumers’ perceptions

- Steph Hill, University of Leicester - Sign the manifesto: Examining corporate advocacy efforts in the creation of a mandate to negotiate a legally binding instrument on plastic pollution

- Dr Tony Walker, Dalhousie University - Government policy responses to curb plastic pollution pre- and post-COVID-19 pandemicKeynote: John Chweya, Kenyan National Waste Pickers - Leveraging global policy to ensure a just transition for waste pickers

Keynote: Von Hernandez, Break Free from Plastic - How can the global plastics treaty serve as a platform for system change?

Panel discussion:

- Von Hernandez, Break Free from Plastic

- Zoe Lenkiewicz, Specialist in Global Waste Management

- Rachel Karasik, Nicholas Institute for Energy, Environment and Sustainability

- Belen Olmos-Giupponi, University of Portsmouth

- John Chweya, Kenyan National Waste Pickers

Short talks:

- Dr James Doherty, Plastic-i Limited - Plastic-i: Enabling solutions to marine plastic pollution with satellite imagery & AI

- Lauren Weir, Environmental Investigation Agency (EIA) - Agriplastics and the UK Food Supply Chain: How addressing policy failings and market powers is the ultimate solution

- Dr Noreen O'Meara, University of Surrey, Dr Tiago de Melo Cartaxo, University of Exeter & Professor Rosalind Malcolm, University of Surrey - Plastics pollution and youth communities: shaping ownership through adaptive legal tools

Panel discussion: Time is of the Essence – Negotiating a plastics treaty fit for purpose

- Chris Dixon, Environmental Investigation Agency

- Esrat Karim, AMAL Foundation

- Tony Walker, Dalhousie University

- Von Hernandez, Break Free From Plastic

- James Wakibia, Environmental Activist and Photojournalist

As you can see from the number of speakers, this was an inspirational and packed event with so many topics covered. I was so pleased to be a part of it and bring an historical context to the proceedings along with the panellists I was speaking alongside.

I learnt so much about the people living with the worst of the plastics pollution and the projects that are attempting to reduce the production and use of materials, those that are exploring ways to prevent the waste ending up in the wrong place, and those monitoring and / or removing it once it is there. It was good to see the use of artificial intelligence in a positive context too.

It was the kind of conference where there was so much to take in that you need more time to explore the subjects covered. I have no doubt that I will be spending lots of time over the coming weeks and months finding out more about the many speakers and the work they are doing.

Louise Dennis, Curator of MoDiP

Wednesday, 12 July 2023

Salter 59 kitchen scales

Once again flicking through the trade journals in our collection and recognising an object that we own has enriched our record with a wealth of information. This time I was looking through an edition of British Plastics from February 1955 and I stumbled across a fabulous article about the manufacture of the Salter 59 kitchen scale. This article has offered up a firm date and title of the object and some fabulous detail about how exactly the case was made and who did the moulding.

|

| Salter 59 kitchen scales, AIBDC : 0_2337 |

Here is the article:

Three

polystyrene mouldings for domestic scale

A great deal of progress has been made lately in the application of plastics to household appliances, especially where streamlined shape, appearance and ease of cleaning are essential properties. This recent trend is exemplified in the modern domestic scale where a number of new or redesigned models have plastics components; in particular polystyrene finding favour on account of the excellent finish obtainable with this material.

The Salter 59 scale uses high impact polystyrene for its scoop, general purpose for the housing, and general purpose for the dial cover, where the glass-like transparency of the material is of special advantage. The moulding is carried out by E. Elliott, Ltd. Birmingham, and the technique used to mass-produce three items mentioned is of additional interest in that all of the finishing, apart from a cementing operation, is carried out at the press.

The pictures on these pages (come and see the article if you would like to see them all) show the stages in moulding the Salter 59 case. Production is carried out on an 8-oz injection machine, using general-purpose polystyrene in a cream (yellow in our case) shade. Injection is at the centre top of the case where a square aperture is later punched out to accommodate a plunger when the scale is assembled.

|

| Punching the square aperture from the housing after moulding, and, right, a housing placed in the jig for drilling in four positions |

At the completion of each cycle the operator clips off the sprue and stamps out the square aperture on an electrically heated punch, the temperature of which accurately maintained by a Sunvic control system. After this the housing is placed in a jig, which is designed both to hold the shape of the moulding as it finally cools and to allow the simultaneous drilling of four 1/16 in holes, two on each side; the purpose of these holes is to accommodate attachment of the inner mechanism of the scale. Drilling is carried out by four drills each operated by an air valve supplied from the normal press air line; a master valve enables the complete system to be switched in and out, and thus cutting out noise when the drills are not actually operating, and thus making the operator's job less fatiguing. The housing then wrapped in tissue and at once packed in a cardboard box for transfer to the Walsall works where the moulding dial cover cemented in.

Production of the dial cover is carried out on a 4-oz machine, using single-impression three-plate tool working with clear transparent material. Gating is at the centre of the cover, and to disguise the tiny scar at this point the mould is blasted over a small circular area, thus producing circle of matt finish in the centre of the cover when moulded. Weight of shot is 1 ½ oz. Removal of the sprue is interesting in that a tapered dowel provides a positive movement of the sprue in the tool, so that after the stripping plate has cleared the moulding , the sprue can be removed backwards from the gate.

The dial covers are wrapped tissue and packed straight from the press and, as previously stated, sent away for cementing into the housing. Thus the handling of both is reduced to the barest minimum, thereby cutting down the possibility of rejects through accidental damage in the factory.

The scoop of the scale is run alternately with the housing. A single-impression tool is used and the scoop is gated on the centre under-surface. The colour used is cream, and the weight of the shot is just over 3 ½ oz. The sprue is removed from the operator, who then packs the scoop in similar fashion to the housing. The scoop is embossed to provide graduations in fluid ounces and pints on the inside.

It is so interesting to see the number of different steps needed and the care given to the end product to ensure it arrived at its destination in good order. I do love finding these fascinating articles.

Louise Dennis, Curator of MoDiP

Wednesday, 5 July 2023

Decarbonisation

This

wine bottle is made from 100% recycled PET |

|

| All of these objects

are sourced

from plant-based materials rather than fossil fuels. Image credit: MoDiP |

In the drive towards becoming net zero, businesses involved with plastics can also try to make efficiencies across their general operations, production processes and supply chains. They might consider switching to low-carbon technologies, using renewable energy sources, adopting closed-loop systems to minimise waste and choosing partners who also prioritise decarbonisation. When areas of unavoidable impact still exist, they might invest in guaranteed carbon offsetting projects, designed to reduce future emissions.

|

Examples of carbon

neutral materials. Image credit: MoDiP |

Katherine Pell

Collections Officer

Wednesday, 28 June 2023

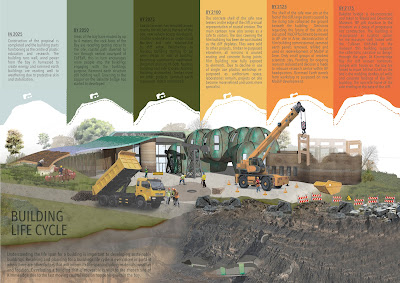

MA Architecture

At the end of last year, an MA Architecture student, Jemma Chapman came in to the museum to explore the use of waste plastics. We talked about a variety of concepts and objects including Greenbrick's building blocks.

|

| Large blue brick, Greenbrick, AIBDC : 008795.3 |

Since meeting with Jemma, she has gone on to develop a rich and evolved proposal called CoPEar - The Centre of Plastic Education and Research, in which MoDiP became a key component.

Wednesday, 21 June 2023

Turner Museum of Glass

Earlier in the year I had the most fabulous ‘school trip’ to Dundee to visit the Plastic: remaking our world exhibition at V&A Dundee. To get the most out of the journey I had a look at some other museums that I could visit on the way. The best fit was another university collection focusing on a single material /material family. That collection was the Turner Museum of Glass at the University of Sheffield where I met with Emily Green, Interim Head of Special Collections, Heritage & Archives and University Heritage Collections Manager.

The core of the Turner Museum collection is 20th

century art glass which was acquired by W.E.S. Turner, Professor of the

Department of Glass Technology, through his personal contacts with glass producers

and designers in many parts of the world from the 1920s to the 1950s. Many pieces were made especially for Turner or

while he was watched. In 1943 Professor

Turner donated his collection to the University of Sheffield to inspire

students and researchers and serve as ‘a counterbalance to the technical

activities in which the department is engaged.’

The collection continues to be added to as the museums acquires work

from contemporary artists in glass.

.jpg) |

| Some of the cases showing the collection including some of the early glass. Image credit: L Dennis |

.jpg) |

| These case show glass from around the world including pieces created by contemporary artists. Image credit: L Dennis |

I wasn’t expecting to see a dress made of glass. The blue fibreglass dress, handbag, shoes and

hat were worn by Helen Nairn Monro on her marriage to Professor Turner in 1943. The dress was designed and made by Messrs

Pettigrew and Stephens, Glasgow and the fabric was created by Glass Fibres Ltd

of Firhill, Glasgow.

.jpg) |

| Fibreglass dress, 1943, made by Messrs Pettigrew and Stephens, Glasgow. Image credit: L Dennis |

I really enjoyed my visit to the collection as it reminded me of my time at Birmingham Museum & Art Gallery which has a fabulous collection of early glass, and I am very grateful to Emily for taking the time to talk to me about the collection.

Louise Dennis, Curator of MoDiP

Wednesday, 14 June 2023

Design for Disassembly

|

| The dental floss container is a good example of a design that can be easily disassembled. Image credit: Katherine Pell |

|

| Myelin cycle helmet, AIBDC : 009452 Image credit: MoDiP |

|

| Bird headphones, AIBDC : 008193 Image credit: MoDiP |

|

| Nike ISPA Link trainers, AIBDC : 009459 Image credit: MoDiP |

Collections Officer